Did you know there is no guidance for temporary ramps in TG20?

The latest of the TG20 amendments, TG20:13, came out in 2014. It was created by the NASC (National Access & Scaffolding Confederation) and aims to impose a good, universal level of consistency in the use of tube and fittings scaffolds. Though it is not a statutory necessity, the TG20 guidelines are taken among contractors and scaffolders to be a core value of their trade. Not only this, following TG20 guidelines ensure that you comply with the Work at Heights Regulations 2005, which is a legal requirement. TG20 guidance covers an array of standard scaffolds such as tied independent access scaffolds, Loading bays, Internal birdcages and more, however TG20:13 does not cover all scaffolds. When it comes to temporary ramps there is no guidance within TG20:13 to fall back on, so a temporary ramp must be constructed from a bespoke design. Here is a quick rundown of some important aspects to consider.

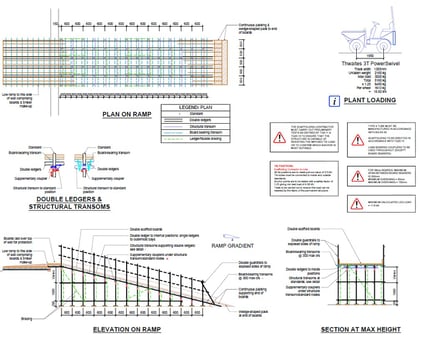

Design

Before any work is started it’s important to have a design for your ramp as it is not considered to be a standard scaffold within TG20:13. The design must be completed by a competent person(s), and take into consideration the rigidity, lifespan, stability and use of the ramp.

Size and purpose

It’s important to consider the size and purpose of the ramp. For instance, if a ramp is being used for the transportation of a vehicle or heavy machinery then it’s crucial to consider the weights of these items, and how their weight is distributed and transferred onto the ramp. For example, a ramp designed for a forklift truck with 4no wheels may be different to a ramp designed for a digger with 2no tracks, even if the weight of both vehicles is the same. This is because the bearing area and spacing of the wheels or tracks may be different giving different loading conditions, so the size of any wheels or tracks and the distances between them along with the weight, are all crucial pieces of information that must be made available to the designer. Often this information can be found within the manufacture’s specification for commercial vehicles. If a ramp is not being used to transport heavy machinery it is still important to consider the purpose of the ramp to ensure it’s designed to support an appropriate load.

Allowable slope angles for ramps

At present there is no guidance for the allowable slope angle for a ramp where the ramp is being used by site operatives. In this situation the main contractor must decide what they feel is an acceptable angle for the particular purpose of the ramp. Where a ramp is being used to transport a vehicle, the main contractor should seek advice from the vehicle manufacturer to ensure the ramp angle is within it’s operating parameters.

Where a ramp is being used by the general public the ramp should be designed to comply with building regulations for wheelchair access. These regulations do give clear guidance on the allowable angle for ramps; however, these angles are very shallow and become even more shallow for longer ramps. There is also a limit to how long a ramp can be before a level landing area is required. This means it’s not a straightforward process to calculate the required length of a ramp for wheelchair access and careful consideration is required to ensure there is adequate space available.

For more information contact Access Design & Safety Ltd, where we can help you create safe ramps and scaffolding designs that are compliant with all the relevant guidance & codes. You can contact us on 01384 459090 or info@designsafe.co.uk